About Us

Innovating Excellence in Material Handling, Silos & Pneumatic Conveying Systems

KI CONEQUIP is a leading engineering company specializing in Material Handling, Fabrication, Storage Silos, Pneumatic Conveying Systems, Mixing, and Process Equipment. With a strong commitment to quality and innovation, we design and manufacture high-performance industrial solutions that enhance productivity across sectors such as cement, chemicals, food processing, plastics, minerals, and general manufacturing.

From bulk material storage silos and air-based conveying systems to customized handling equipment and precision fabrication, our products are engineered for seamless operation, efficiency, and long-term durability. Backed by years of expertise and an advanced manufacturing setup, KI CONEQUIP delivers end-to-end solutions that meet global standards and empower industries with reliable, future-ready performance.

More About

15+

YEAR WORK IN INDUSTRYEngineering Excellence in Material Handling & Pneumatic Conveying Systems

KI CONEQUIP is a trusted engineering and manufacturing company delivering end-to-end solutions in Material Handling, Fabrication, Pneumatic Conveying Systems, Bulk Storage Silos, Mixing Solutions, and Process Automation. With a commitment to precision, innovation, and long-term performance, we design and build robust industrial equipment for the cement, chemical, minerals, food processing, plastics, and general manufacturing sectors.

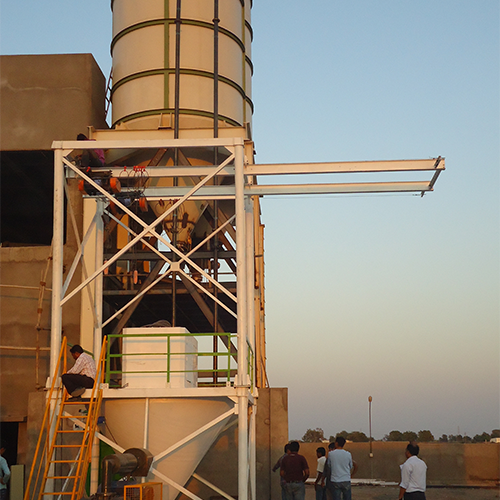

Our Material Handling & Storage solutions include screw conveyors, bucket elevators, dust-free bag-loading systems, rotary airlocks, diverter valves, and customized steel silos for powders, granules, and bulk solids. Every system is engineered for smooth flow, contamination-free handling, and maximum operational efficiency.

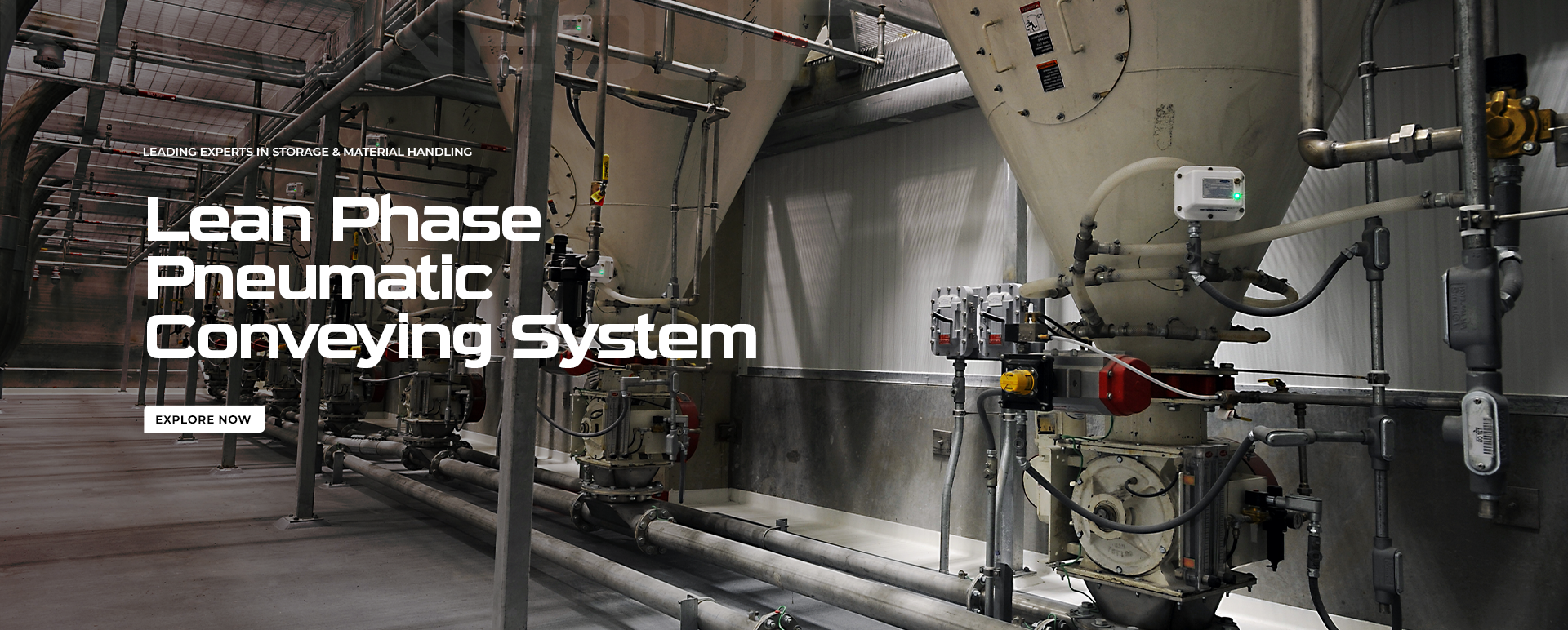

We specialize in designing Pneumatic Conveying Systems for lean phase, dense phase, and vacuum conveying applications—ensuring efficient, enclosed, and automated transfer of bulk materials. With expertise in pipeline design, system integration, and air control technology, KI CONEQUIP provides energy-efficient conveying solutions for even the most challenging materials.

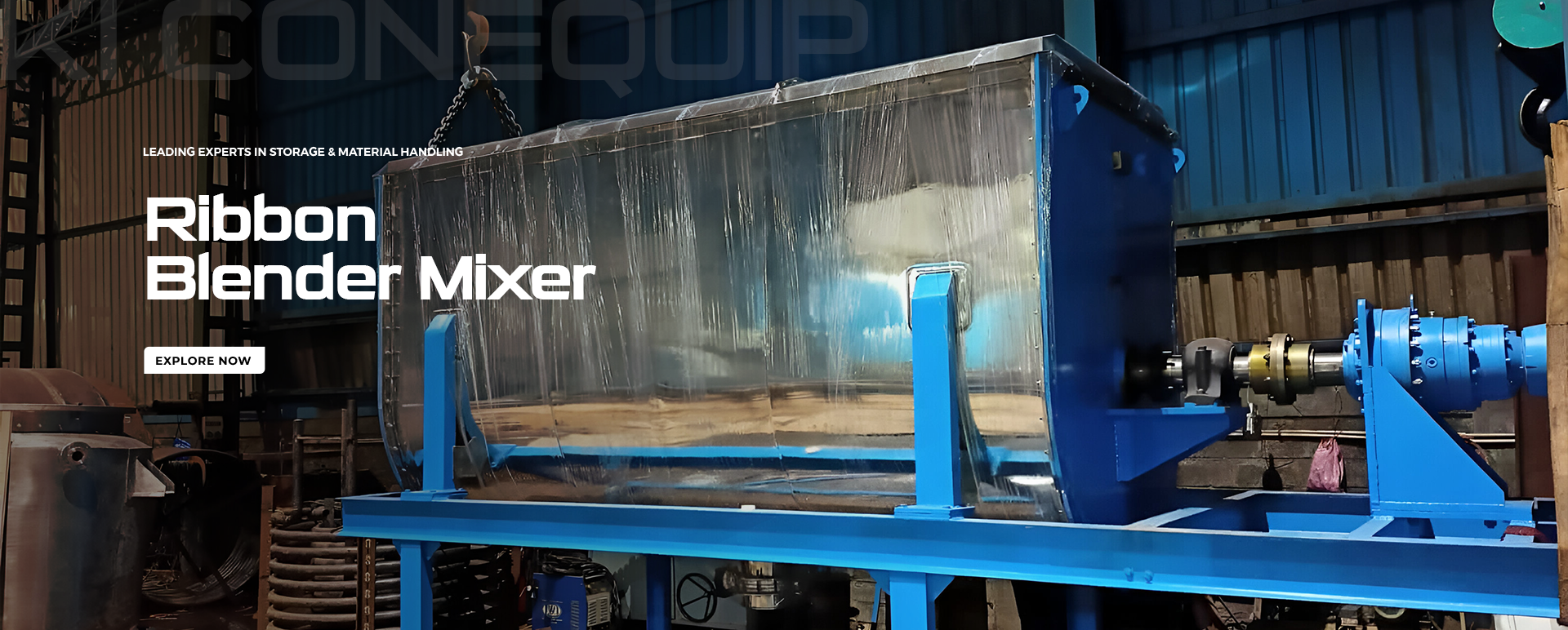

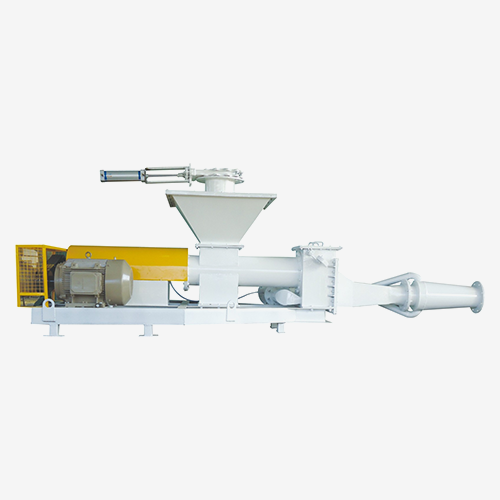

Our Fabrication Division manufactures precision-built hoppers, tanks, pressure vessels, silos, chimneys, and heavy-duty steel structures using high-grade materials and advanced welding procedures. In Mixing Systems, we offer a range of high-performance mixers including Ribbon Blenders, Plough Shear Mixers, Twin Shaft Mixers, and Pan Mixers designed for uniform, consistent, and efficient mixing of various materials.

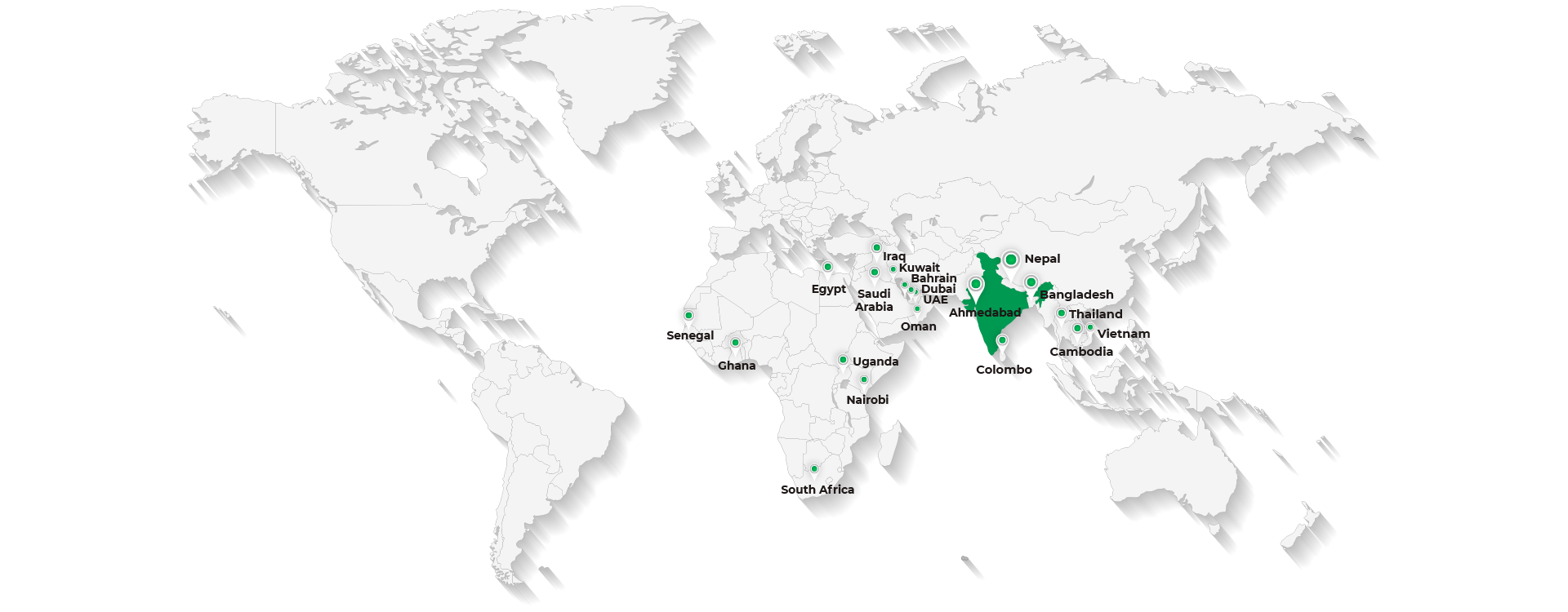

KI CONEQUIP serves industries across India and 30+ countries worldwide including the USA, UAE, Australia, Malaysia, South Africa, and the United Kingdom. Our solutions are known for reliability, customization, and long service life—backed by a strong engineering team and dedicated after-sales support.

With advanced manufacturing facilities in Ahmedabad, Gujarat, and a client-first approach, KI CONEQUIP continues to set benchmarks in bulk material handling, conveying technology, and industrial processing—empowering industries to operate with precision, consistency, and confidence.

Request A Quote