Share your details &

our experts will respond within 12 hours.

Years Experience

Happy Clients

Countries Exported

Expert Engineers

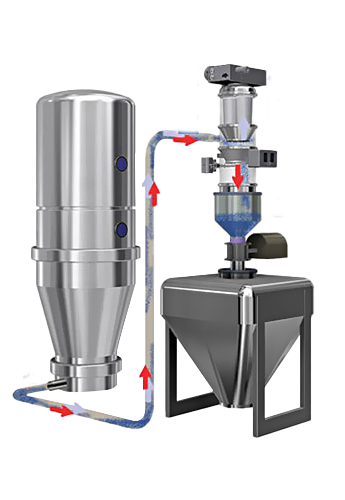

KI CONEQUIP Jumbo Bag Unloaders are designed for safe, dust-free, and efficient emptying of FIBC / Big Bags used for bulk powder and granule handling. Built with a robust frame and optimized discharge mechanisms, they ensure smooth material flow while preventing bridging, spillage, or contamination. Ideal for food, chemical, plastics, minerals, and process industries, each system can be integrated with screw feeders, rotary airlocks, pneumatic conveying, and downstream processing lines.

Have a look at some of our successfully delivered projects across Material Handling, Pneumatic Conveying, Mixing, Processing, Fabrication, and complete turnkey industrial installations in India and worldwide.

Looking for Aluminium Silos, Pneumatic Conveying Systems, Batching Plants or Turnkey Material Handling Solutions? Our experts are here to guide you with the best-fit options for your industry needs.

We follow a structured engineering approach to deliver reliable, efficient and customized bulk material handling solutions for industries worldwide.

STEP -01

We evaluate project needs, material type, and storage capacity to plan the right solution.

STEP -02

Custom-designed layouts and technical drawings to ensure efficiency and safety.

STEP -03

Precision-built equipment delivered, assembled, and installed on-site with expert supervision.

STEP -04

System testing, quality checks, and training before final project delivery.

Get expert consultation, custom configurations, and competitive quotes from our engineering team.