Share your details &

our experts will respond within 12 hours.

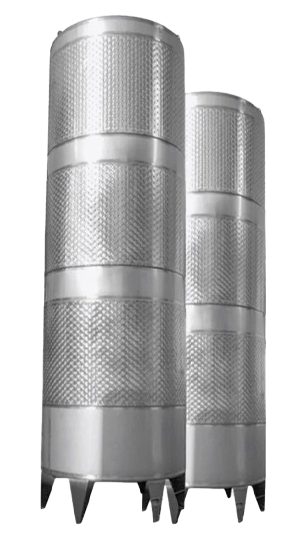

Welcome to Ki Conequip — Specialists in SS Storage Silos & Stainless Steel Tanks

Years Experience

Happy Clients

Countries Exported

Expert Engineers

KI CONEQUIP SS Storage Silos and Stainless Steel Tanks are designed for hygienic, corrosion-resistant, and long-lasting storage of powders, liquids, chemicals, food ingredients, and process materials. Manufactured using premium-grade SS304/SS316/SS316L, these silos and tanks ensure contamination-free storage, excellent cleanability, and superior durability for all industrial environments—including food, pharma, chemical, plastics, and mineral handling applications.

Have a look at some of our successfully delivered projects across India and worldwide.

Looking for Aluminium Silos, Pneumatic Conveying Systems, Batching Plants or Turnkey Material Handling Solutions? Our experts are here to guide you with the best-fit options for your industry needs.

We follow a structured engineering approach to deliver reliable, efficient and customized bulk material handling solutions for industries worldwide.

STEP -01

We evaluate project needs, material type, and storage capacity to plan the right solution.

STEP -02

Custom-designed layouts and technical drawings to ensure efficiency and safety.

STEP -03

Precision-built equipment delivered, assembled, and installed on-site with expert supervision.

STEP -04

System testing, quality checks, and training before final project delivery.

SS silos and tanks are suitable for powders, granules, liquids, slurries, food ingredients, chemicals, pharma materials, oils, and corrosive or high-purity products that require hygienic and contamination-free storage.

Stainless steel offers superior corrosion resistance, hygiene, long service life, and easy cleaning. SS304/SS316 materials prevent rust, contamination, and chemical reactions—making them ideal for food, pharma, chemical, and high-purity applications.

Yes. KI CONEQUIP provides fully customized solutions for height, diameter, storage capacity, cone angle, discharge type, insulation, material grade, and integration with conveying, batching, and processing equipment.

Absolutely. SS storage silos and tanks integrate seamlessly with pneumatic conveying systems, rotary airlocks, vibratory feeders, bag filters, screw conveyors, weighing systems, and automated dosing or batching units.

Installation time depends on size and site requirements. Most SS storage silos and tanks are installed and commissioned within 5 to 18 days, including mounting, alignment, safety checks, and equipment integration.