Share your details &

our experts will respond within 12 hours.

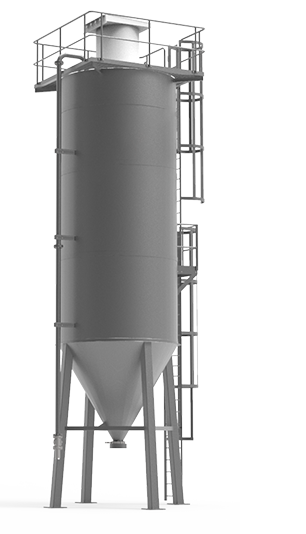

Welcome to Ki Conequip — Premium Aluminium Storage Silos

Years Experience

Happy Clients

Countries Exported

Expert Engineers

KI Conequip Aluminium Storage Silos are engineered for high-performance bulk material storage such as cement, fly ash, minerals, and powder materials. Designed for durability, low maintenance, and corrosion resistance, our silos ensure smooth material flow, dust-free operation, and long-term reliability. Available in custom sizes and modular configurations, they integrate seamlessly with pneumatic conveying systems, screw conveyors, batching plants, and industrial handling equipment for turnkey productivity.

Have a look at some of our successfully delivered projects across Material Handling, Pneumatic Conveying, Mixing, Processing, Fabrication, and complete turnkey industrial installations in India and worldwide.

Looking for Aluminium Silos, Pneumatic Conveying Systems, Batching Plants or Turnkey Material Handling Solutions? Our experts are here to guide you with the best-fit options for your industry needs.

We follow a structured engineering approach to deliver reliable, efficient and customized bulk material handling solutions for industries worldwide.

STEP -01

We evaluate project needs, material type, and storage capacity to plan the right solution.

STEP -02

Custom-designed layouts and technical drawings to ensure efficiency and safety.

STEP -03

Precision-built equipment delivered, assembled, and installed on-site with expert supervision.

STEP -04

System testing, quality checks, and training before final project delivery.

Aluminium silos are suitable for storing cement, fly ash, lime powder, minerals, dry chemicals, resin powders, and other bulk industrial materials that require controlled and dust-free storage.

Aluminium is lightweight, corrosion-resistant, reduces foundation load, requires minimal maintenance, and offers a longer lifespan especially in humid or aggressive environments compared to steel silos.

Yes. KI CONEQUIP designs and manufactures silos according to project capacity, site layout, discharge requirements, and space availability, ranging from small batch silos to large-capacity storage systems.

Absolutely. Our silos connect seamlessly with screw conveyors, pneumatic conveying systems, weighing units, and automated batching plants for smooth and efficient material handling.

Thanks to modular bolted construction, silo installation and commissioning typically takes between 3 to 15 days depending on the capacity and project scope.