Share your details &

our experts will respond within 12 hours.

Welcome to Ki Conequip — Specialists in Dry Mix Mortar Production Plants

Years Experience

Happy Clients

Countries Exported

Expert Engineers

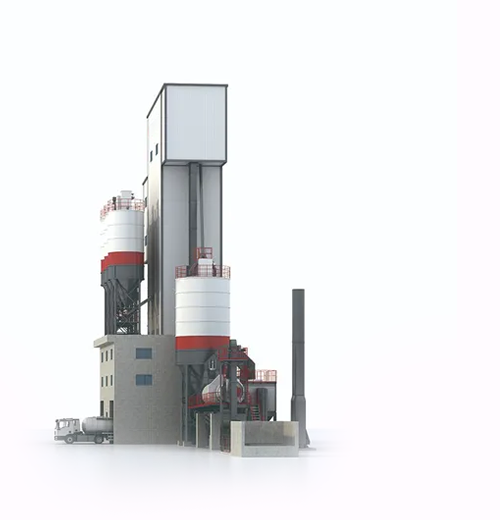

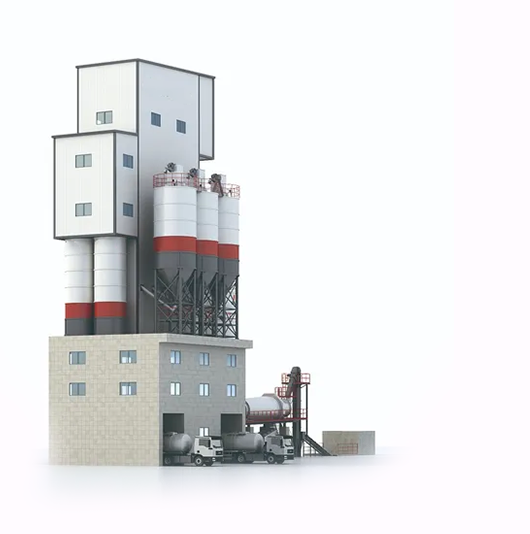

Ki Conequip Dry Mix Mortar Plants are designed for high-efficiency production of pre-mixed construction mortars including tile adhesives, wall putty, plaster, grout, bonding agents, and cement-based mixes. Engineered with precision mixing technology, automated batching, and dust-free material handling, these plants deliver consistent product quality and optimized productivity. Our systems are ideal for construction chemical manufacturers, ready-mix mortar companies, building material factories, and industrial production units requiring continuous, reliable, and uniform mortar output.

Have a look at some of our successfully delivered projects across Material Handling, Pneumatic Conveying, Mixing, Processing, Fabrication, and complete turnkey industrial installations in India and worldwide.

Looking for Aluminium Silos, Pneumatic Conveying Systems, Batching Plants or Turnkey Material Handling Solutions? Our experts are here to guide you with the best-fit options for your industry needs.

We follow a structured engineering approach to deliver reliable, efficient and customized bulk material handling solutions for industries worldwide.

STEP -01

We evaluate project needs, material type, and storage capacity to plan the right solution.

STEP -02

Custom-designed layouts and technical drawings to ensure efficiency and safety.

STEP -03

Precision-built equipment delivered, assembled, and installed on-site with expert supervision.

STEP -04

System testing, quality checks, and training before final project delivery.

Dry Mix Mortar Plants handle cement, sand, additives, polymers, fillers, binders, mineral powders, and specialty chemicals used in products like wall putty, tile adhesive, plaster, grout, and repair mortars.

Dry Mix Mortar Plants ensure consistent quality, accurate formulation, faster production, reduced labor dependency, and improved workability—making them essential for efficient and reliable construction material manufacturing.

Yes. Ki Conequip offers fully customized Dry Mix Mortar Plants based on capacity, automation level, mixing technology, product formulation, packaging requirements, and integration with silos and conveying equipment.

Absolutely. The plant integrates seamlessly with cement silos, sand dryers, screw conveyors, bucket elevators, mixers, weighing systems, and automatic packing machines for a complete production line.

Installation typically takes 10 to 30 days, depending on plant size, automation requirements, dryer setup, silo integration, and the complexity of material handling systems.