Share your details &

our experts will respond within 12 hours.

Welcome to Ki Conequip — Specialists in Pallet Conveyor & Transfer Automation Systems

Years Experience

Happy Clients

Countries Exported

Expert Engineers

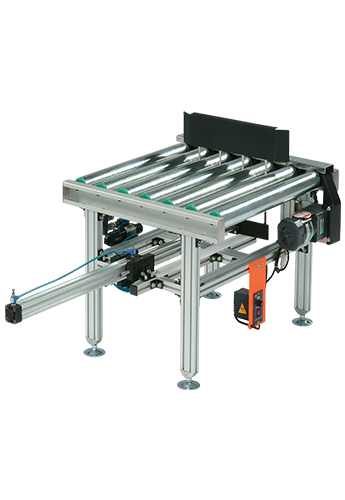

Ki Conequip Pallet Conveyor & Transfer Systems are designed for reliable, automated movement of pallets, crates, bins, and heavy loads across industrial facilities. Engineered for continuous-duty performance, these systems ensure smooth material flow, reduced manual handling, and seamless integration with automated storage, packaging, and production lines. Ideal for logistics centers, manufacturing plants, warehouses, FMCG units, food & pharma operations, and heavy-load industries, each system is built for efficiency, safety, and long-term durability.

Have a look at some of our successfully delivered projects across Material Handling, Pneumatic Conveying, Mixing, Processing, Fabrication, and complete turnkey industrial installations in India and worldwide.

Looking for Aluminium Silos, Pneumatic Conveying Systems, Batching Plants or Turnkey Material Handling Solutions? Our experts are here to guide you with the best-fit options for your industry needs.

We follow a structured engineering approach to deliver reliable, efficient and customized bulk material handling solutions for industries worldwide.

STEP -01

We evaluate project needs, material type, and storage capacity to plan the right solution.

STEP -02

Custom-designed layouts and technical drawings to ensure efficiency and safety.

STEP -03

Precision-built equipment delivered, assembled, and installed on-site with expert supervision.

STEP -04

System testing, quality checks, and training before final project delivery.

Pallet conveyor systems efficiently handle pallets carrying cartons, bags, drums, containers, bulk materials, finished goods, raw materials, FMCG products, food items, and industrial components with ease and stability.

Pallet conveyor systems increase productivity, reduce manual labor, eliminate handling errors, improve safety, and support continuous material movement—making them essential in packaging, warehousing, logistics, and manufacturing automation.

Yes. Ki Conequip customizes pallet conveyors based on plant layout, load capacity, transfer type (roller/chain/90-degree), speed, automation level, and integration with AS/RS, robots, or packaging lines.

Absolutely. Pallet conveyors integrate seamlessly with robotic pick-and-place units, palletizers, AGVs/AMRs, stretch wrapping machines, labeling units, and warehouse automation systems.

Installation generally takes 5 to 15 days, depending on conveyor length, transfer points, automation level, load capacity, and integration with existing material handling or warehouse systems.